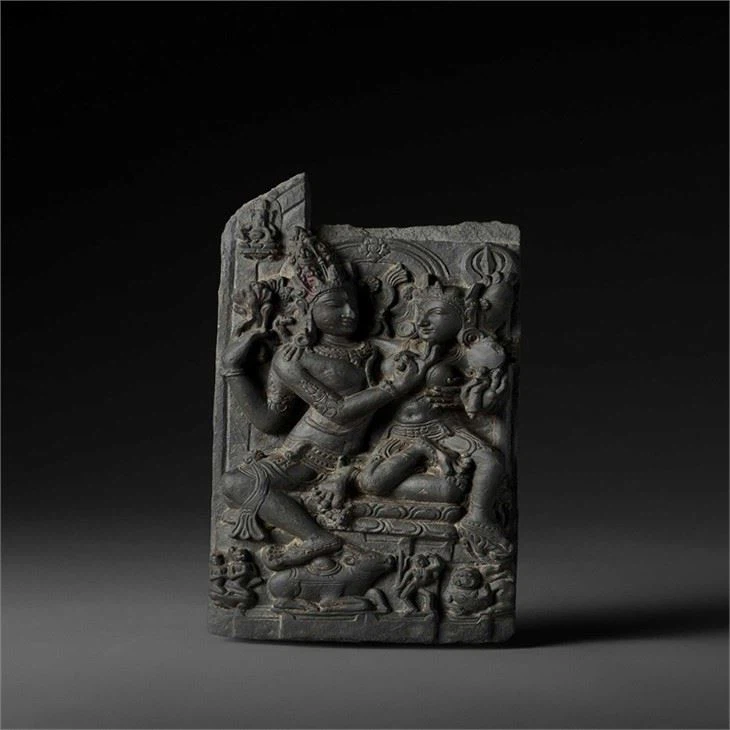

The engraving process of black stone carving is roughly divided into three processes: reclamation, refinement and polishing :

1)reclaim

This can be divided into three steps:

cut away unnecessary part of the stone blank until the basic contour of the carving is cut.

To further knock out the basic outline of the body and face relation from the rough contour of the sculpture.

Then further drive the carving production and processing into a thickness of about 1 cm from the finished product specification.

Because every stone carving craftsman has a different habit, the three whole processes of production and processing are sometimes carried out alternately, and there is no fixed procedure. This process mainly uses special tools such as large, medium and small chisels, but nowadays, they are basically replaced by electric or pneumatic tools.

2)Refine

Breaking down is to cut away the unnecessary part left. Sculpting is a key link in the development of the art of modeling stone sculptures of Buddha. Whether the carving is good or not lies in this link, and it must be carefully crafted. The key special tools for fine-cutting applications are tooth chisel, flat chisel, stone set, etc.

3)polishing

Polishing is the basis of fine black stone carving crafts. According to the expression effect necessary for the final brand image, the whole or part of the carving is polished and polished with special grinding tools to highlight the layering of the stone and increase the quality of the stone carving. The actual effect of glossiness enhances its artistic appeal. The key special tools necessary for grinding and polishing are polishing machine, sand wheel, sanding sandpaper, polishing paste and so on. Naturally, according to the different regulations of the designer, the surface production and processing of the acid etching and sandblasting methods will naturally be carried out. If it is carved by each division, it must be assembled first, and the areas that are not suitable for the assembly must be modified and polished.

Finally, cleaning and maintenance are carried out. It is to wash away the dust and dirt on the stone and the sticky and residual super glue. According to the type of stone and the design plan, the safety protection agent or glazing oil specified on the above.