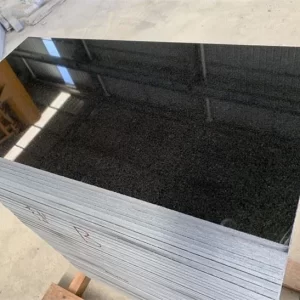

Processing for black granite countertops

Cutting blocks.

It is the process of cutting the blocks into rough boards with a circular saw or a sand saw according to the customer’s processing requirements. After cutting, an inspection should be carried out first, the qualified wool boards should be retained, the unqualified ones should be removed, and the ultra-thick wool boards should be post-processed.

polishing

coarse grinding:

The qualified products in the previous process and the thickness-determined wool board are firstly ground with a grinding machine. At present, the grinding machines are mainly walk-behind grinding machines and multi-head continuous grinding and polishing machines.

Fine grinding:

Use a polishing machine to polish the qualified wool board or the repaired wool board one by one into a rough board

Usually, the gloss requirement of European and American orders should be above 90°

trimming

Each part of the table panel is cut out – the main table, the side splash, the back splash and the front etc. When cutting, pay attention to black granite surface, avoid cracks, black spots, color lines, stains…

At the same time, it is necessary to ensure that the geometric dimensions, angular dimensions and diagonal dimensions of the finished product after cutting are accurate, and no edge chipping or corner drop is allowed. If the back of the countertop needs to be glued, edges and corners of the back should be intact to facilitate subsequent edge processing.

edge processing

Edge processing refers to the processing of the edge of the countertop, as simple as grinding straight edges or processing into special-shaped edges (bull nose edge, duckbill edge, etc.). If the customer does not require the edge to be thickened, the countertop can be directly processed (turned edge). If the customer requires the thickened edge, then the edge of the countertop should be thickened first.

dig hole

It is to open the basin hole, the faucet hole and the installation hole of the under counter basin on the countertop. The hole is usually opened by a machine, or the four corners of the wash basin are opened by the opener first, and then manually cut.