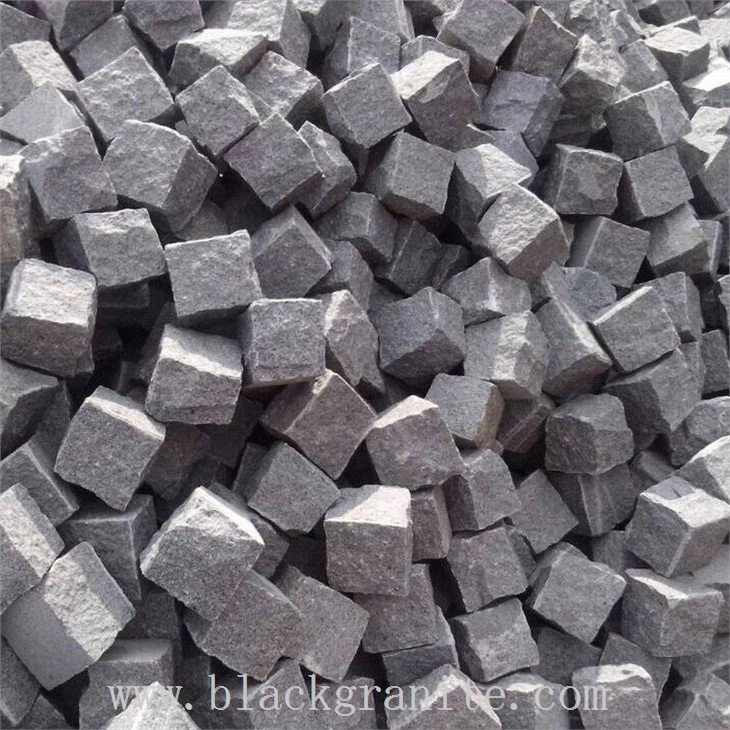

Our Factory Equipment To Produce Black Granite Cobbles

Eastwood Black Granite factory is equipped with more than 35 sets of advanced stone processing machines such as Gang saw, infrared ray cutting machine, Automatic polishing machine, etc… to produce different black granite products, however, to make Black Granite Cobbles, normally after cut into different sizes of cubes of cobbles, we hand split six sizes or one size, leave other sizes to be machine cut, or flamed one or five surface of cobbles, do as per customers’ request. Natural split cobbles and flamed cobblers are ideal choice for exterior paving since they are non-slip for safe.

How To Pack Black Granite And Limestone Cobbles And Setts

To pack Black Granite Setts 100x100x50, if customers aim at lowest cost and just make them safe, normally we pack directly into fumigated wooden crates and then reinforce. To match the modern and luxurious standard package for our wholesaler or supermarket, we work out the newest package way for our black granite cobbles.

How We Deliver Black Granite Cobbles to Wholesaler or Building owners

After we finish proceeding different type products of Black Limestone Cobbles, we deliver to customers according to order quantity, normally we ship by FCL and LCL shipment, when order quantity is not too much, we can also arrange deliver by courier, like DHL or FEDEX, EMS or TNT. We have professional team from inspecting to packing, loading and delivery, welcome to search any black granite cobbles from our website for your nice buildings.

Basic Information

| Material | Black Granite Cobbles, Black Limestone Cobbles |

| Surface Finishing | Honed, Flamed, Natural Split, Pineapple etc |

| Standard Size | 5x5x5cm, 10x10x5cm, 10x10x10cm, 20x10x10cm Or Customized |

| Cut to | Gang Saw Slabs, Tiles, Basin Sink, Countertops, Mosaics, Carvings, etc |

| Mainly Use | Outdoor Landscaping |

| Supply Ability | 10000 to 15000 square meters per month |

| Payment Terms | T/T, L/C, Western Union |

| MOQ | 50 Square Meters |